Extracts are highly complex mixtures obtained from a plant material. They consist of active compounds and non-active compounds. Latter are often referred to as ballast. Active compounds are responsible for the activity of the extract, like anti-inflammatory action. Non-active compounds are divided in two subgroups: desirable and undesirable.

Desirable non-active compounds have a positive impact on the extract, for example they increase the stability or solubility of the active compounds. Undesirable non-active compounds negatively affect the extract; they frequently contribute to an unpleasant aroma, intensive colour, or support the growth of microorganism; therefore they are usually removed in the process of purification of extracts.

Extracts are produced by extracting a plant material with solvents. Main reasons why extracts are manufactured are:

- reduction of volume of plant material,

- increasing stability of product,

- increasing concentration of active compounds,

- removal of undesirable compounds.

For food and medical use, non-toxic solvents are used like water and ethanol (alcohol). This is especially important in liquid and thick extracts where the solvent is not completely removed. Sometimes the use of more toxic solvents like acetone and methanol is necessary, but after the extraction these solvents must be completely removed from the extract.

After complete removal of the solvent, dry extracts are obtained, which can be in form of a powder or a semi-solid to solid material. Depending on the solvent used, extract can be water-soluble (hydrophilic) or oil-soluble (lipophilic). The use of solvents can be avoided by employing novel technology, like the extraction with supercritical carbon dioxide.

The composition of extracts is strongly affected by the quality of the plant material and the manufacturing process; therefore quality assurance and quality control is absolutely necessary. The chemistry of the plant depends on the environmental factors and the processing of the plant. It is influenced by the quantity of the sunlight, water, fertilizers etc. Constant quality of plant material can be assured by cultivation, harvesting and processing in accordance with Good agricultural and collecting practice.

For the production of the extract a well-defined and repeatable process must be established, preferably according to Good manufacturing practice. For example, the composition of the extract can change significantly with variation of the following parameters:

- temperature,

- herbal drug to solvent ratio,

- time of extraction.

In quality control the concentration of active compounds is measured and the absence of possible contaminants, such as heavy metals, pesticides and microbial toxins must be checked as well.

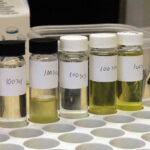

Since active compounds of Cannabis species are cannabinoids, which are poorly water-soluble, fairly lipophilic organic solvents, like ethanol and isopropanol are used for the extraction of the plant material.

Unfortunately, with these solvents several undesirable non-active compounds are extracted as well, like chlorophyll, which imparts deep green colour to extracts, unsaturated lipids, which are prone to oxidation and develop rancid odour and taste, and terpenoids, which impart a burning or bitter aftertaste of the extract.

Total supercritical carbon dioxide extract have similar properties but even higher viscosity and are very difficult to process. Selective supercritical carbon dioxide extraction is therefore employed for a more focused extraction of desired compounds.

Literature

Blaschek W, Ebel S, Hilgenfeldt U, Holzgrabe U, Reichling, Schulz V. HagerROM 2008 – Hagers Enzyklopädie der Arzneistoffe und Drogen. Wissenschaftliche Verlagsgesellschaft, 2008.

DerMarderosian A, Beutler JA. Marijuana. In: The Review of Natural Products. Wolters Kluwer Health, 2014.

European Medicines Agency. Declaration of herbal substances and herbal preparations in herbal medicinal products/traditional herbal medicinal products. Accessed: 24. 08. 2016.

European Medicines Agency. Good agricultural and collection practice for starting materials of herbal origin. Accessed: 24. 08. 2016.

European Medicines Agency. Specifications: test procedures and acceptance criteria for herbal substances, herbal preparations and herbal medicinal products/traditional herbal medicinal products. Accessed: 24. 08. 2016.

Veitch NC, Smith M, Barnes J, Anderson LA, Phillipson JD. Introduction. In: Herbal Medicines, Fourth edition. Pharmaceutical Press, 2013: 4-26.

Wichtl M. Allgemeiner Teil. In: Teedrogen und Phytopharmaka. Wissenschaftliche Verlagsgesellschaft mbH, 2009: 3-39.